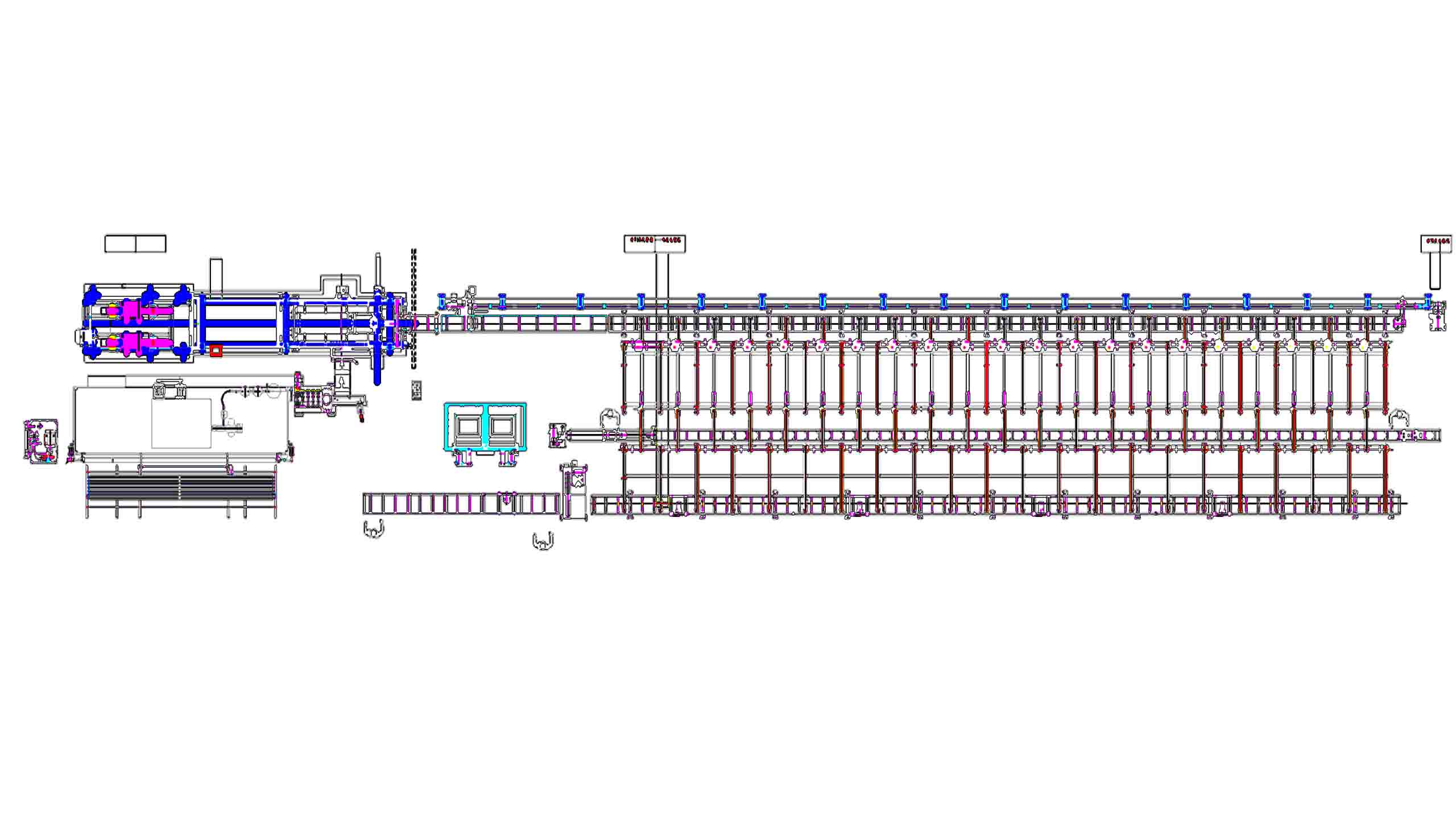

We offer turnkey plant service for customers from layout to machinery design,manufacture,installation,debugging, training aftersale service and continuous parts supply

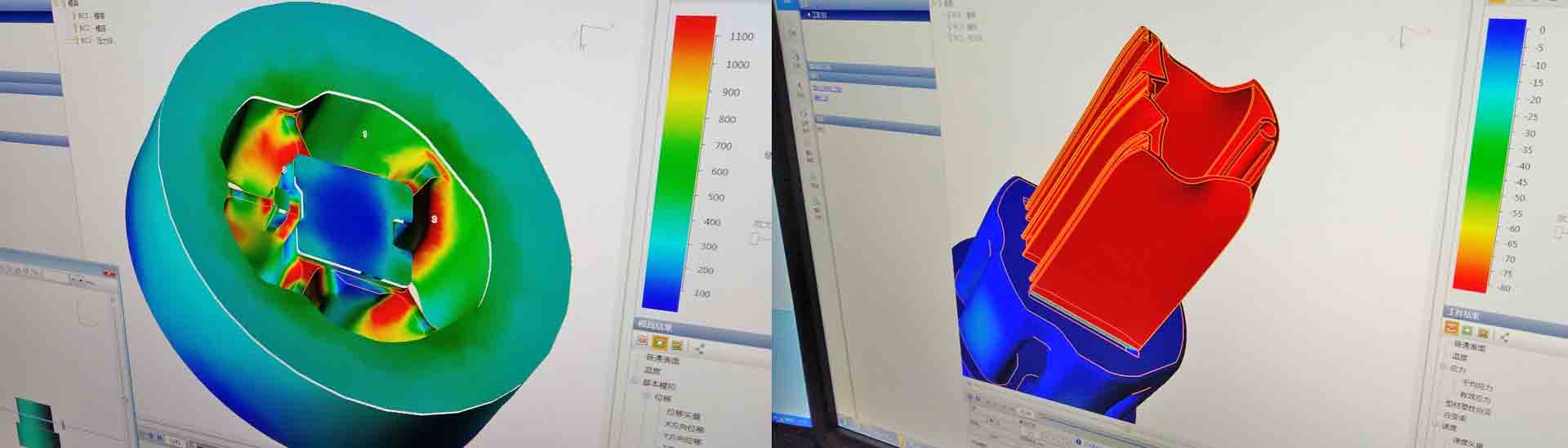

Serve customers with our many years experience, improve product added value with the latest technology, and provide the most satisfactory solutions for every customers

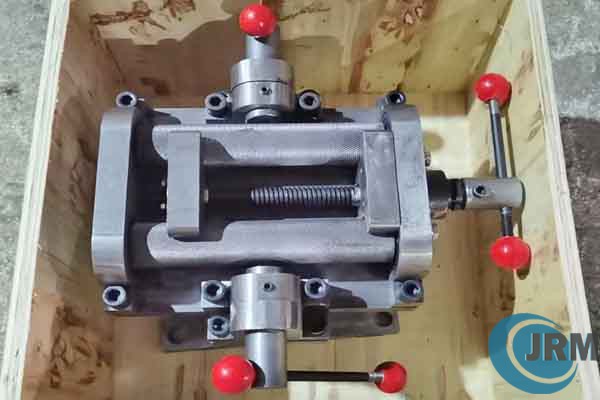

With a positive attitude and a good impression, we can provide customers with high quality, high efficiency and high level of service to solve customer's problem quickly

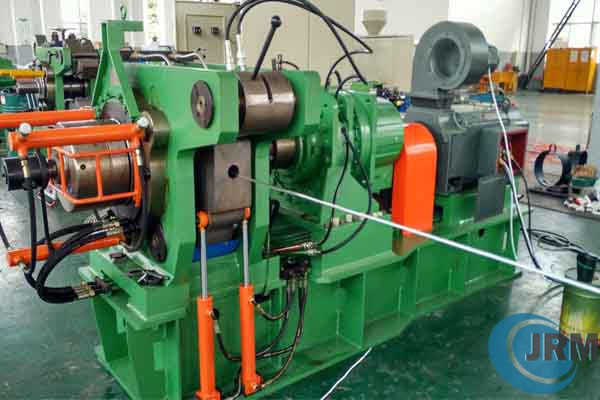

Continuous high quality service for customers, in order to do this we need to keep a peaceful heart, good attitude for a long time, and only good service to enhance customer's loyalty