Crystallizer for aluminium billet casting machine

Crystallizer for aluminium billet casting machine

Crystallizer for aluminium billet casting machine

Crystallizer for aluminium billet casting machine plays a crucial role in the aluminum billet casting process. The function of the aluminum billet crystallizer is to cast molten aluminum liquid into aluminum billets, and its principle is to solidify and shape the aluminum liquid through the crystallization process.

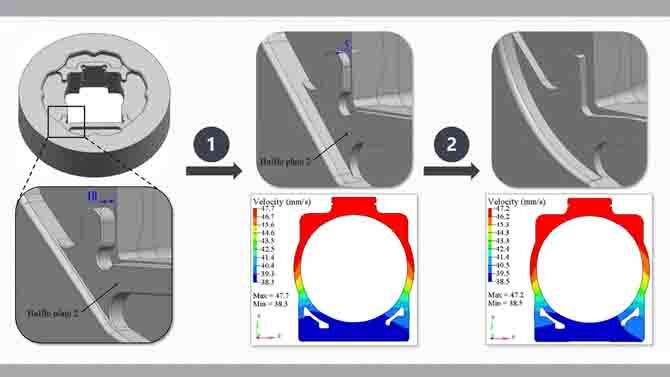

The structure of an Crystallizer for aluminium billet casting machine consists of a crystallizer body, a baffle plate, a sealing ring, a cover plate, an adapter plate, and a graphite ring. The principle is to open holes in the crystallizer separately, and the casting oil and compressed air are transported to the corresponding holes in the crystallizer through pipelines. The molten aluminum is cooled and solidified into a shell at the graphite ring, and as the casting machine moves down, the aluminum continuously fills the shell. The water sprayed from the crystallizer cools the shell again, and the molten liquid inside the shell gradually solidifies, forming an aluminum billet.

This process involves flowing the melted aluminum liquid into the distribution tray through a flow channel. When the aluminum liquid accumulates to a certain extent in the distribution tray, it is solidified through a crystallizer. Crystallizers are usually composed of an upper ring and a lower ring. The upper ring has multiple drainage holes on the ring wall near the lower ring, which helps to evenly cool and solidify the aluminum liquid.

The principle of crystallizer is based on the cooling and solidification process of aluminum liquid. When high-temperature aluminum liquid flows into the crystallizer, it comes into contact with the crystallizer. As the crystallizer is usually wrapped by a cooling water jacket, the aluminum liquid quickly cools down and begins to crystallize. This process is continuous, and the aluminum liquid begins to form a preliminary solid layer on the inner wall of the crystallizer. As the aluminum liquid continues to flow in and cool, this solid layer gradually thickens, eventually forming a complete aluminum billet. The design of the crystallizer ensures uniform cooling and solidification of the aluminum billet, avoiding the adhesion and slag inclusion problems that may occur when the aluminum liquid flows directly into the chassis.

The aluminum billet crystallizer is made of forged aluminum raw material with high processing density, smooth surface, and good high temperature resistance. It is the core component of the released aluminum rod through CNC machining and drilling.

In practical operation, the maintenance and handling methods of the crystallizer have a direct impact on its performance. If not handled properly, it may lead to a decrease in the quality of the ingot, resulting in surface pits, tensile marks, and cracks. Therefore, regularly cleaning the alumina flakes on the inner wall of the crystallizer to ensure their smoothness and absence of impurities is a key step in ensuring the quality of the aluminum billet.

If you have any question about Crystallizer for aluminium billet casting machine,write mail or add my whatsapp please.

Abel Tsao

Email: sales@rextrusion.com

Whatsapp:0086-15906155538