Conform extrusion die and conform machine

What is continuous extusion?

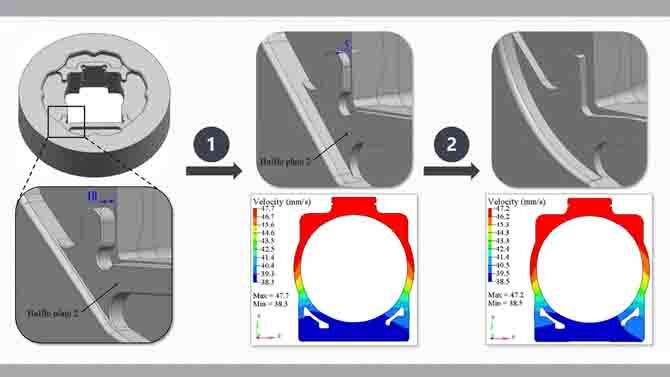

The continuous rotary extrusion equipment heats feedstock metals by using friction. When deformation temperature is achieved, the metal will be able to be created into desired shapes under die and wheel.

In the course of rotary extruding, the extrusion wheel with groove continuously rotates. By means of the friction between the wheel groove and feedstock, the feedstock is continuously transported to the extruder, allowing extremely long end products to be created due to the unceasingly delivery movement. The development of such a process truly realizes the continuous production, so this technique has been widely employed.

Complete processes such as:feedstock de coil straightening,cutting, cleaning,continuous extrusion, cooling, length metering, and take-up.

Continuous rotary extrusion line supports copper, brass,aluminum, and their alloys. It is a great solution to manufacture solid and hollow section products:conductor wires, trolley wires, busbars, strips, round tubes, multi-port tubes etc. These extruded products are widely used for transformers, electric motors, switching devices, electric locomotives, as well as the evaporator and condenser units of refrigerators and air conditioners.

Advantages of continuous extrusion

1. Shorter Process Flow and Lower Equipment Investment

Continuous rotary extrusion machines can make feed rod into shaped products, without heating equipment, acid pickling line, trimming machine etc. While ensuring simplified production flow and reducing equipment investment, this also contributes to environmental protection;

2. Lower Energy Consumption

In continuous extrusion process, the heat is generated via friction and deformation process. Thus, there is no need for additionally operations such as annealing and heating, which significantly cuts off energy consumption.

3. Low Waste but High Rate Finished Products

Continuous extrusion machines won’t produce wastes such as scrape edge. This ensures very high material rate accordingly. continuous extrusion equipment for copper and aluminum products offers first pass yield up to 95% above.

4. Low Labor Intensity

The entire continuous rotary extrusion line, characterized by computerized intelligent control,only two operators control the production line. The continuous extruding machine is suitable for manufacturing products of variable specifications by using different extrusion dies. Additionally, the extrusion dies can be changed in a fast and convenient way. Such a machine is great for forming products with a great variety of specifications.

5. Same Product Quality

High quality extrusion dies guarantee the optimal forming precision and satisfactory sectional shapes.That completely eliminates the internal defects of feeding metal materials.

6. Higher Electric Conductivity

Through continuous rotary extrusion, crystalline grains of metal materials are rearranged, and the density of the feedstock is increased. This makes sure extruded copper and aluminum products have reduced resistivity and improved conductivity, even though the demand of annealing is eliminated.

7.continuous extruding machines require smaller installation space and easy working.

What kind products from continouse extruion machine?

If you want to find continuous extrusion die supplier,contact me freely please. www.rextrusion.com whatsapp 008615906155538 sales@rextrusion.com